3 August

A Proven Plan for IIoT Success

The Internet of Things has the enticing transformative potential for manufacturing. Though many who have tried have failed. There’s a way to succeed, and it is more simple than you may think.

Data today is a lot like solar power. There’s an enormous amount of it—more than 2.5 million terabytes created daily—and everyone would love to find a way to harness its power for their operations. But it’s a complicated process, your current situation is still tenable and it might be better to let someone else figure it out.

With solar, that strategy is pretty sound. Photovoltaic panels have been around since the 1950s, yet the technology accounted for a scant 2% of power generated in 2016, according to the U.S. Energy Information Administration. However, with the much younger Internet of Things, the network of 9 billion+ sensors and devices collecting data on everything and everywhere to make more informed decisions faster and often automatically, you can’t just let the power pass you by.

This doesn’t appear to be a problem, as every business sector knows knowledge is power, and there are infinite benefits from understanding more about their operations and customers. Even the consumer side, with smart fridges, thermostats and a legion of other gadgets and devices, is discovering the advantages.

The total number of connected things could reach 20 billion by 2020, Gartner predicts. By 2025, the Industrial Internet of Things (IIoT) category alone could be worth just south of $1 trillion, according to Grand View Research, Inc. This massively broad subsection provides cost-savings and efficiency improvements at every level of manufacturing, from design to delivery, with process monitoring, predictive maintenance and asset tracking being obvious standouts.

Using Siemens’ EnergyIP Energy Efficiency Analytics (EEA), auto supplier Gestamp was able to cut energy consumption by 15%.

For large scale operations, like international auto supplier Gestamp, which has 32,000 employees and 100+ production plants, implementing Siemens’ EnergyIP Energy Efficiency Analytics (EEA) cloud-based solution reduced energy consumption by 15%.

“Knowing how much energy we’re consuming, where, and in what form is the key to reducing our energy costs,” says Santiago Esarte, the head of Gestamp’s energy efficiency department.

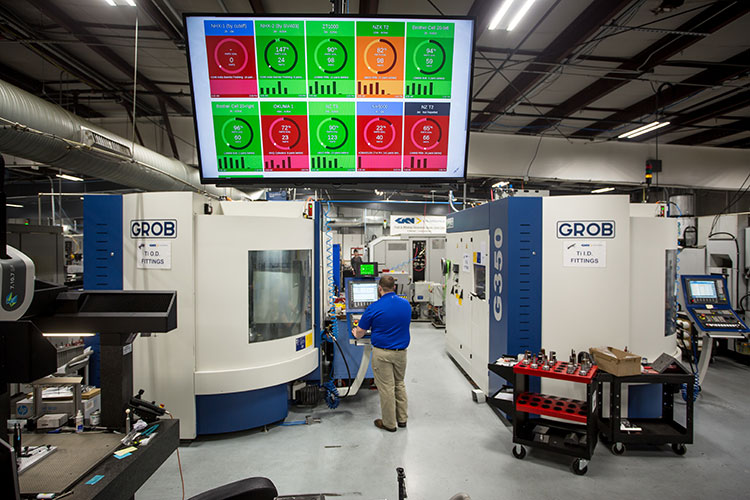

Even small machine shops achieve immediate results. Using machining software called MachineMetrics helped an advanced manufacturer with 50 technicians become 15 to 20% more efficient and save an estimated $1 to 2 million in capital expenditures over a three-year span, its president Steve Capshaw says.

Again, instituting an IIoT solution is a complicated process and cannot be overstated. When the Internet itself achieved prominence in the 1990s, everyone knew they could make money from it and they had to act fast. The Dot Com Bubble burst in 2002 showed that time to market isn’t everything. A really good idea—and execution of said idea—is more critical to lasting success than being first.

I assume that should be common knowledge by now in the C-Suite, but I learned at 19 from an extremely salty chief petty officer on a Norfolk pier what that makes “u” and me. Hype is going to happen; stupidity is going to follow. And the hype is strong with IIoT right now, though Cisco’s report bandied about last year that 75% of IoT projects fail has probably weakened that in the minds of some.

Two things to note about that: First, 60% of these projects shut down at the proof of concept stage, and not after a year of time and investment on the factory floor. Second, the definition of failure here means they weren’t a “complete success.”

I’d like to know of the 1,845 IT and business decision-makers surveyed, how many were super critical of themselves and/ or had unrealistically ambitious expectations. But then again, there’s probably no one in the tech world like that, right?

The IIoT is gigantic, but not too big to help SME’s, such as machine shops gather and leverage data to bring about dramatic efficiency improvements.

Those are minor caveats, though. Like the IoT, the survey does hold incredibly valuable insights and backs up the advice dozens of experts have relayed to me over the three years I’ve been writing about it.

The human factor topped the factors for success, with 54% citing collaboration between IT and the business side as the most important factor.

According to Alexandra Rehak, practice head for the IoT team at analytics consulting firm Ovum, IIoT success, especially when machine learning and more automation are added to the mix, is contingent on getting buy-in from everyone who will be involved.

“A lot of IIoT success is around understanding the process really well ahead of time, where you can get value from automating, and making sure the people involved in the process are onboard and willing to share knowledge,” she says.

For example, think of a predictive maintenance case where management wants real-time temperature or dust monitoring of equipment to alert when a machine will fail, allowing employees to take action and avert a costly production line shutdown. The IT department and/or integrators set up the infrastructure between sensors, analytics platforms, the MES, and so on, but then leave it to the technicians and operators to run the equipment. These are the real experts, the ones who will be inputting the data and who will need to train the algorithm, Rehak argues

“[Deploying an IIoT solution] disrupts the process in the business,” says the analyst with 20 years experience. “You have to be really sure the people working with and supporting them get why they’re doing it and understand what the benefits are.”

At SME’s such as VSS, this was crucial as operators were needed to add context at the CNC machines HMI. Even the smartest sensor or advanced AI cannot compare with a human’s ability to asses a situation. They can alert that power to a machine went down and calculate how that will affect daily throughput, but couldn’t know that it was because someone tripped over a cord and unplugged the machine.

Along with a people-first approach, Rehak says not to get swept up in the hype.

“IoT can be transformational in a positive way, but a small step by step approach is what we advise,” she says.

A measured approach is how Gestamp reached its levels of efficiency. The initiative started in 2014 in two plants and then started to grow a year after. Currently, 15 plants are connected, with all new plants slated to use the data solution.

One other thing to note: the IoT might actually be better for the environment than solar, as Gestamp alone reduced CO₂ emissions by 14,000 tons in 2016, and 16,000 less in 2017. Siemens has taken this success story and configured it to run on its open, cloud-based IoT operating system, MindSphere so that businesses of every size and industry can scale up to achieve similar results.

Article originally sourced from IndustryWeek